PAPTIC, an innovative environmental new material replacing paper and plastic is rewriting plastic packaging present and future for good.

Obviously, our planet has a plastic pollution problem and it’s snowballing, but so it is public awareness and action from innovative companies somehow to tackle the assignment to rewrite the matter.

From National Geographics: Fast Facts About Plastic Pollution

Each year, an estimated 18 billion pounds of plastic waste enters the world’s ocean from coastal regions. 40 percent of plastic produced is packaging, used just once and then discarded.

Consumers are increasingly aware of the importance of making sustainable choices. Packaging materials are playing a decisive role moving forward. Carrier bags will continue to grow in importance as a tool in marketing and brand building activities- these bags must be sustainable but that shouldn’t be done at the expense of the overall product and brand experience.

There are solutions as they happen. Paptic, is rewriting the plastic waste history.

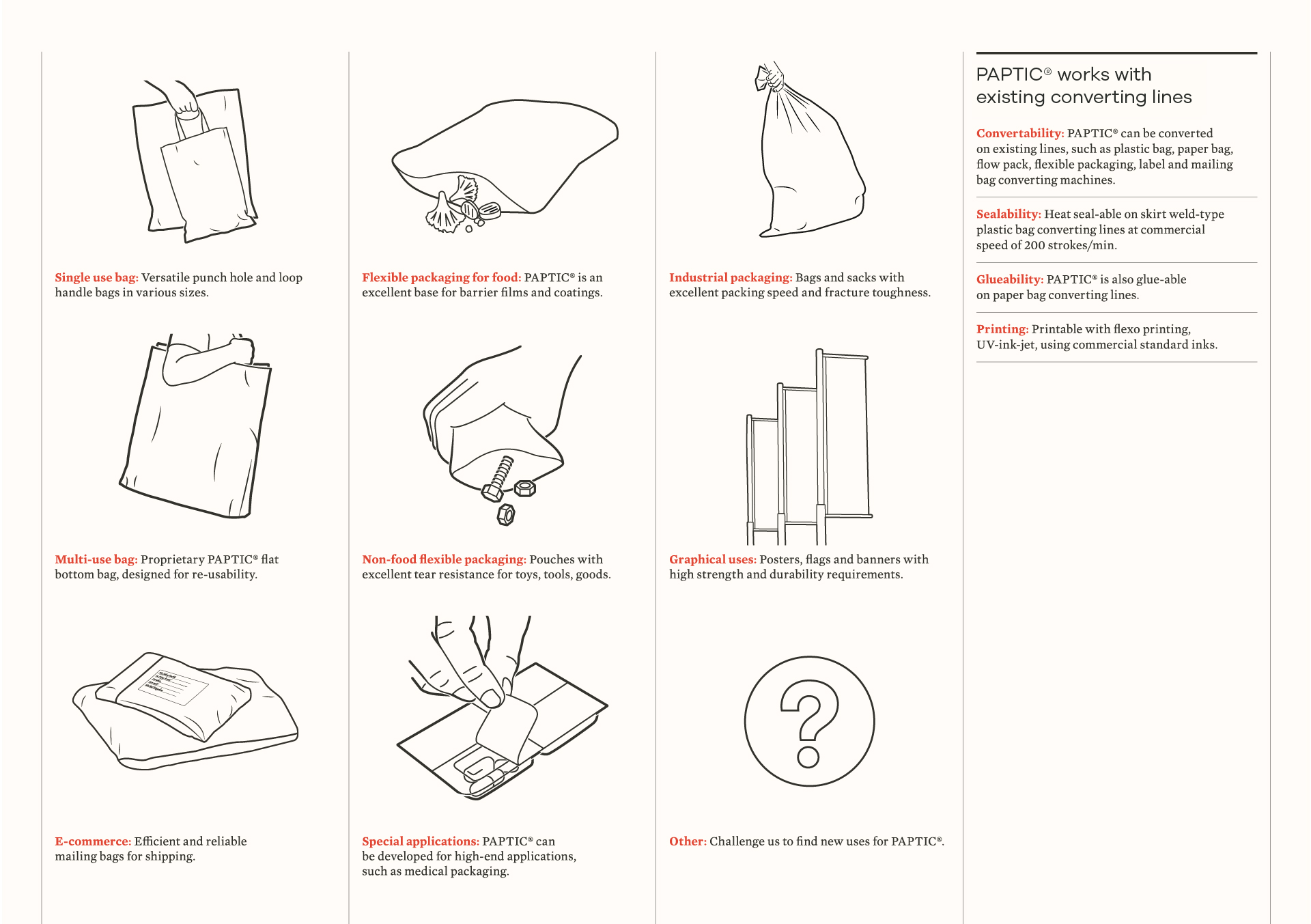

Paptic is a Finish based innovation company producing and industrializing a sustainable material that is different from any other material currently on the market. Paptic packaging is resistant, it does not tear easily, it resists humidity and more importantly it looks and feels more like textile than paper or plastic which is ideal for reusability. Everything a high-quality retail brand like but it’s ecological and sustainable.

Plastic Ethics wanted to know what Paptic’s packaging are made of?

Paptic Ms. Daniela Bqain Marketing Coordinator told us : « PAPTIC main raw material is wood fibre and then we have some biobased, biodegradable man-made fibre also in the fibre matrix to receive the required haptic and technical properties. We do not have any plastic in the material, so also no oxo-biodegradable plastic. PAPTIC is made with conventional paper machines but with a patented foam forming technology, which is a more resource efficient and environmentally friendly process than the production of conventional paper. »

About Paptic's technical characteristics is details :

The Paptic material is produced using a novel paper production technology called foam forming. Wood pulp is the main raw material, similarly to paper, but value adding raw materials such as man-made fibres can be added to create the unique product characteristics such as textile like tactuality, high tear strength and weldability. The material is also mineral free and hence can be used to protect or wrap fragile materials (e.g. leather, jewellery)

The sustainability of Paptic is built around 6 core aspects:

renewable raw materials: the wood comes from controlled and sustainably managed forests- no carbon tied to the ground is brought to atmosphere because of Paptic

re-usability: consumers are willing to reuse Paptic many times due to its look & feel and technical performance (resistance and foldability)

recyclability: the high quality wood fibre is recycled into other packaging products (the standard Paptic material can be recycled with cardboard); the identified recycling system for Paptic encourages consumers to recycle

resource efficiency: Paptic technology allows not only to use less material but also to optimise the use of resources by choosing the most adequate raw materials to achieve a certain outcome. For example, the resistance of the material is increased by using the right raw material combination and through the extremely good formation of the sheet rather than by increasing the weight per square meter. The Paptic production process is also more environmentally friendly (smaller carbon footprint, more resource efficient) than the production processes of e.g. plastic or paper.

biodegradability: the wood and other fibres in Paptic® biodegrade in the nature. Paptic bags are also far less probable to end up into the sea thanks to the fact that they start to decompose already in the ground

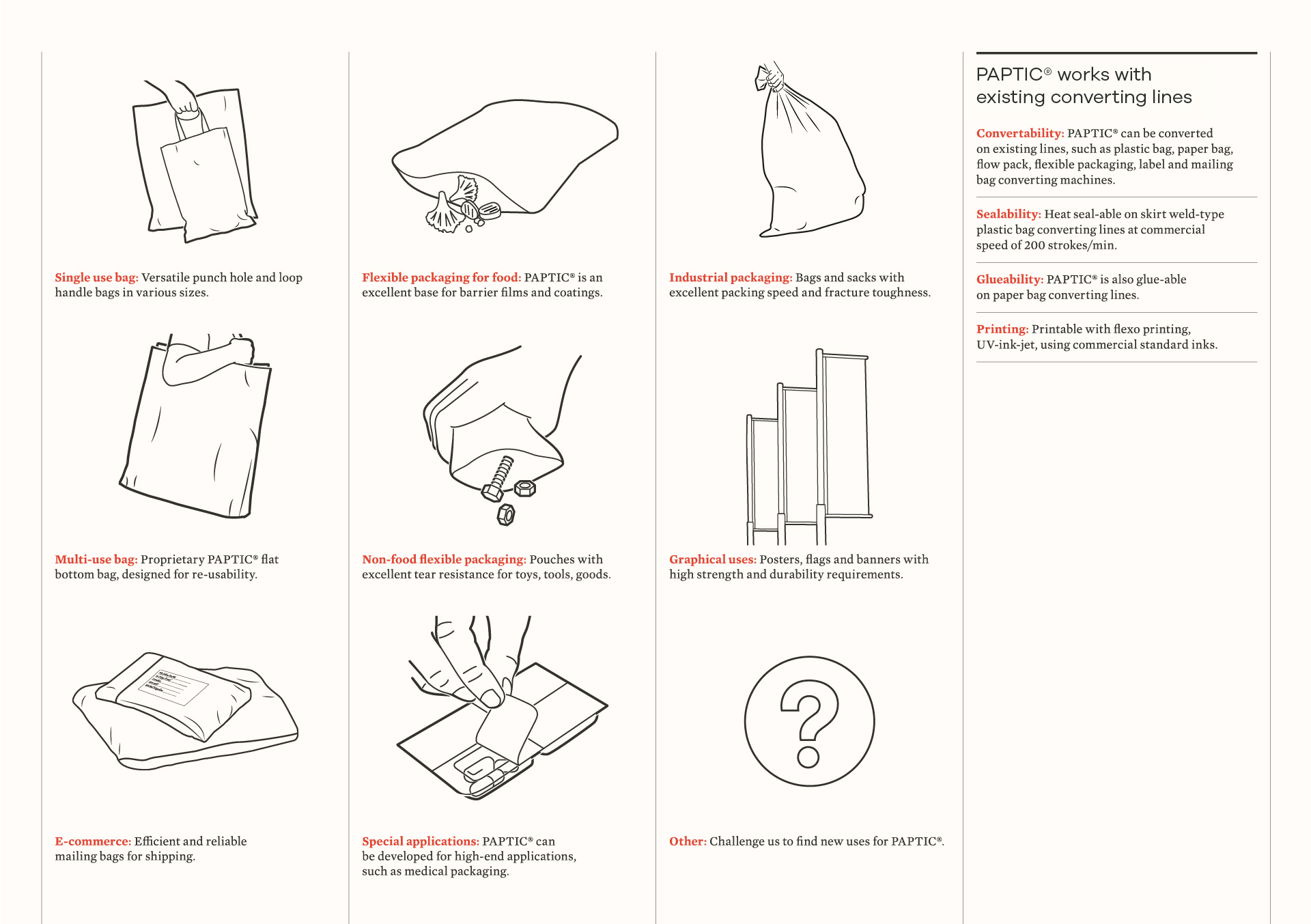

circular economy: Paptic does not require new infrastructure - existing paper production technology (i.e. machines and mills) is used to produce Paptic, and the existing converting lines can be used with Paptic

Full factsheet and products descriptions can be downloaded clicking this link

You even order samples here: https://paptic.com/sample-request

Paptic has been recognised for its sustainable credentials

- Winner of Bio-based Product of the Year 2017 (Biobased Live, Amsterdam, June 2017)

- 2nd position of Innovation Award “Bio-based Material of the Year 2017” (International

Conference on Biobased materials Live, Cologne, May 2017)

- Finalist of LVHM Innovation Award (Vivatech, Paris, June 2017)

- Finalist of the LuxePack in Green competition (Luxepack, Monaco, October 2017)

- Winner of the ExpoLive Innovation Award Grant (ExpoLive, Dubai, August 2017)

- 3rd place in European Paper Recycling Awards (Brussels, October 2017)

- Finalist of PPI Innovation Award (CEPI European Paper Week, Brussels, November

2017)

We wish them a lot of success and bright future for the sustainability of our planet. You can visit their website following this link : https://paptic.com/